Advantage:

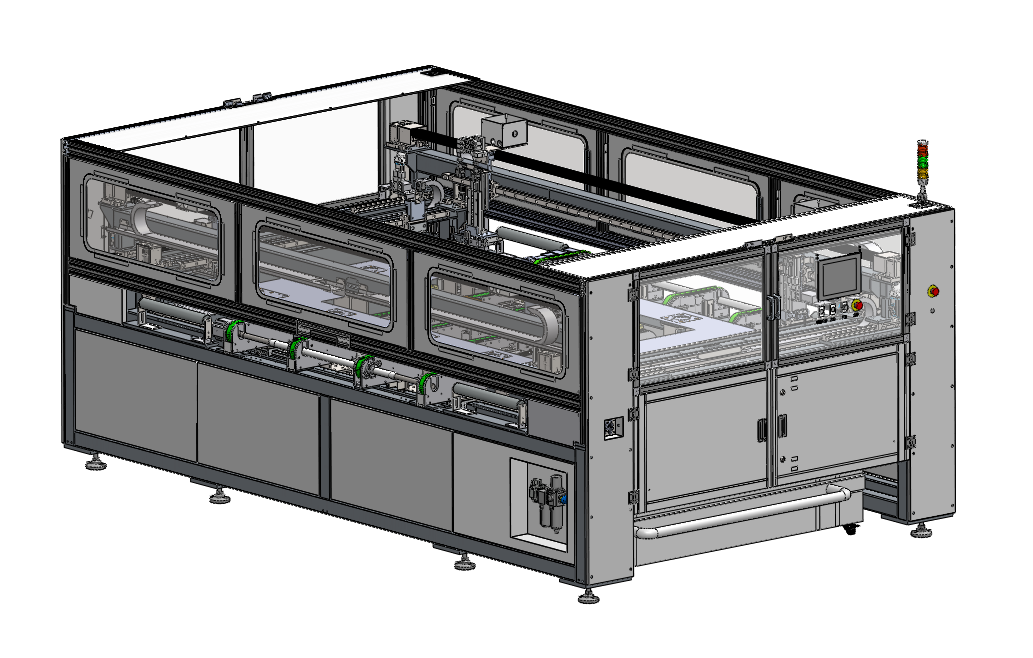

The long and short sides and suckers can be adjusted quickly and the modules can be changed easily;

The equipment includes a collection box to collect waste for easy cleaning;

The material clamping mechanism at the end of the equipment can effectively clip the residual materials around the module;

Install 8 imported blades, fast cutting, long wear life;

The four sides are driven by servo motor, driven by synchronous belt, guided by linear guide rail and cutting cycle at the same time, with high efficiency, short beat, accurate positioning and stable operation;

Elastic contact between cutting knife and glass, adjustable contact pressure, convenient pressure adjustment, perfectly avoid the phenomenon of hidden crack defect and laminate burst caused by cutting pressure.